Packaging Machine

Whether it is diapers, women’s sanitary pants or sanitary napkins, all belong to health products, must be strictly isolated from pollution, prevented from moisture and ash, therefore, health products can not be sold naked, must be strictly packaging before being sold on the market.

In addition to ensuring hygiene, the packaging of sanitary products also plays a trademark role. The production of sanitary products requires special licenses and production trademarks, and often the packaging of sanitary products plays a role in demonstrating the brand and production qualifications. With the development of The Times, packaging has also become a one-time job that can be completed on the packaging machine, and Womeng, China leading factory’s packaging machine can meet all your needs.

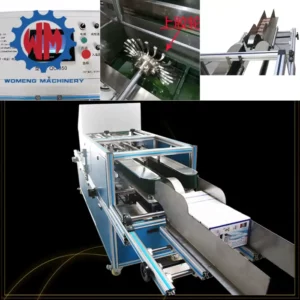

Diaper packaging machine is a device specially used for automatic packaging and sealing diapers. It can efficiently package diapers on the production line, improve production efficiency and ensure product quality.

Functioning parts of our packaging machines

1.feeding system: used to transport diapers on the production line to the packaging machine. A conveyor belt, vibrator, or other device may be used to stabilize and correctly feed the diaper into the packaging machine.

2.packaging material supply system: used to supply packaging materials, usually plastic film or paper boxes. These packaging materials are used to wrap and seal the diaper in subsequent steps. For instance, diaper packaging machine provided by WOMENG.

3.folding and positioning system: the diapers are folded and positioned to ensure that they are in the correct position during the packaging process. This is usually done with devices such as robotic arms, conveyor belts, or vacuum suckers.

4.sealing system: used to seal and fix the packaging material on the diaper to ensure the sealing and integrity of the package. This can be done using heat sealing techniques, tape sealing, or other sealing methods.

5.detection and debugging system: used to detect problems that may occur in the packaging process, such as missing seals, misalignment or defects, and automatically exclude unqualified products.

6.control system: through computer control or PLC (programmable logic controller) to monitor and control the operation of the packaging machine. It can adjust speed, set parameters, record production data, etc.

Why do we recommend buyers to choose our packaging machine?

- Improve production efficiency: The packaging machine has the ability of high-speed packaging and sealing, which can quickly handle a large number of diapers and improve the production capacity and efficiency of the production line.

- Ensure the quality of packaging: The packaging machine is packaged in an automated way, which can ensure the packaging quality and appearance consistency of each product.

- Reduce human error: Our packaging machines have a high degree of automation, reducing the intervention of human operations during the operation process, thus reducing the probability of error.

- Cost savings: Packaging machines can reduce labor costs because it reduces the need for manual packaging. In addition, the automated packaging process also reduces the incidence of waste and defective products, saving production costs.

Key strengths of WOMENG as leading Packaging machine manufacturers and suppliers:

- Established Presence:

- Almost two decades of experience in the industry.

- Specialized Focus:

- Primary focus on diaper machine production.

- Comprehensive Expertise:

- Engaged in R&D, manufacturing, and sales of paper equipment.

- Skilled Workforce:

- Comprises highly skilled sales and technical teams.

- Robust Infrastructure:

- Backed by comprehensive support facilities.

If you have a need or interest for adult diaper packaging machines, please call WOMENG, China, we guarantee to provide you with thoughtful OEM service and amazing wholesale prices!