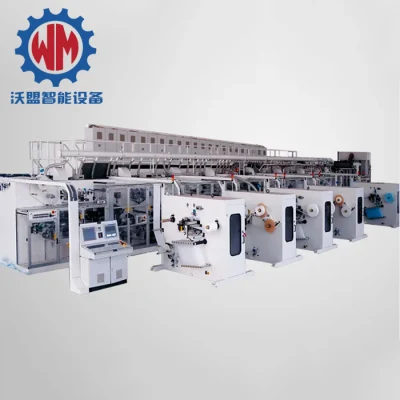

In the world of hygiene product manufacturing, efficiency, reliability and precision are of utmost importance. One name stands out in this sector – WOMENG, a leading sanitary napkin packing machine suppliers. Known for its innovative designs and high-quality machinery, WOMENG is revolutionizing the industry with its fully automatic sanitary napkin making machines.

Revolutionary Designs: The Future Of Sanitary Napkin Production

WOMENG’s sanitary napkin production and packing machines are at the forefront of technological innovation. These machines are designed to streamline the production process, offering a high-speed, efficient solution for sanitary napkin manufacturers. With precision engineering, these machines ensure that each sanitary napkin is perfectly produced and packed, ready for distribution.

WOMENG Sanitary Napkin Making Machines: The Key to Efficient Production

Sanitary napkin making machines are essential for the production of feminine hygiene products. These machines are designed to automate the entire manufacturing process, ensuring efficiency, accuracy, and cost-effectiveness. With the right machine, manufacturers can streamline their operations, increase production capacity, and deliver sanitary napkins that meet the highest standards of quality.

Panasonic: Unleashing the Power of Full Servo Drive System

Panasonic is a renowned global brand known for its excellence in servo systems. WOMENG proudly incorporates Panasonic’s full servo drive system into their sanitary napkin making machines. This advanced drive system ensures precise control over the machine’s movements, resulting in improved efficiency, reduced downtime, and enhanced product quality. With the flexibility to customize the servo system according to buyers’ specific requirements, WOMENG’s machines provide manufacturers with unparalleled versatility.

Mitsubishi: Empowering Control with PLC And LED Touch Screen

Mitsubishi, another esteemed brand, brings its expertise in control systems to WOMENG’s sanitary napkin making machines. The machines are equipped with a PLC control system that allows for seamless automation and precise control over various production parameters. The LED touch screen intesrface provides a user-friendly experience, enabling operators to monitor and adjust machine settings effortlessly. Additionally, WOMENG machines can be configured with an HDTV monitor from Mitsubishi, enhancing visibility and facilitating real-time monitoring of the production process.

Why Choose WOMENG And Our Partner Brands?

Partnering with WOMENG for your sanitary napkin making machines offers several advantages. Here are some key reasons to consider:

- Reliability and Trust: WOMENG has established a reputation for delivering reliable and high-quality machines. Their partnership with globally recognized brands like Panasonic and Mitsubishi ensures the utmost reliability and performance.

- Customization Options: WOMENG understands that every manufacturer has unique requirements. Their machines can be customized according to specific needs, ensuring optimal production efficiency and compatibility.

- Cutting-Edge Technology: By incorporating brands like Panasonic and Mitsubishi, WOMENG stays at the forefront of technological advancements. Manufacturers can benefit from the latest innovations and enhancements, keeping them ahead of the competition.

- Comprehensive Support: WOMENG provides comprehensive support, including installation, training, and after-sales service. Their team of experts is dedicated to ensuring that customers receive the necessary guidance and assistance throughout the entire process.

Our fully automatic sanitary napkin manufacturing machines optimize every stage from material feed to pack through advanced drive and control systems. Let us list the other features below:

Feeding and Bonding

WOMENG machines incorporate precision cut-off systems for non-woven materials. Recoilless feeding maintains tension for jam-free transport to shaping systems. Full-servo drives delicately bond layers into napkin shapes via hot melt or latex methods. Digital control synchronizes components.

Precision Forming

Forming drums precisely contour napkin outlines. Servo motors adjust strip windings to ensure uniform densities. Heated moulds set 3D shapes thoroughly. Ultrasonic or laser sealing head options customize absorption systems. Real-time monitoring prevents defects.

High-Capacity Output

WOMENG machines produce up to 4000-6000pcs/hr through fast feeding, forming cycles below 1 second. Intelligent quality checks flag irregularities automatically. Multi-shift operation maximizes equipment utilization.

Pre-slit Wing Design

Customizable wings integrate pre-cut activation tapes for leakage-proof adhesion. Precision slitting achieves close fit. Automatic tamping presses ensure robust sealing. Steam sterilization sanitizes surfaces hygienically.

Packaging Automation

Integrated weighing, counting and wrapping systems package orders precisely according to customer needs. PLC controls interface packaging directly to maximize non-stop output. Adjustable formats suit various box sizes.

By equipping manufacturers with advanced, customizable full-servo driven machines, WOMENG Machinery sets partners up to meet booming demand for feminine hygiene products sustainably through maximized efficiency and minimized waste.

A New Level of Efficiency: The Fully Automatic Sanitary Napkin Making Machines

The crown jewel in WOMENG’s machinery lineup is the fully automatic sanitary napkin making machine. This state-of-the-art machine integrates all stages of sanitary napkin production into one seamless process. From the initial processing of raw materials to the final stage of packaging, this machine does it all, significantly reducing manual labor and production time.

As a leading supplier of feminine hygiene product machinery, WOMENG is committed to helping manufacturers maximize output efficiencies. Their sanitary napkin machines achieve industrial speeds above 600-800 pieces per minute while maintaining exceptional quality standards.

Streamlined Process

WOMENG machines integrate precision components that seamlessly synchronize all process stages. Raw materials like non-woven fabrics are fed reliably into shaping systems at precise unwinding tensions. Full-servo drive motors sculpt napkin contours thoroughly yet delicately in mills of seconds.

Digital Control

Programmable logic controllers govern operational parameters and product changeovers through intuitive touchscreen HMIs. Setup recipes optimize variables like bonding pressures, heating times and line velocities. Remote diagnostics aid quick issue resolutions to minimize downtime. Production data supports lean improvements.

Consistent Quality

Critical quality checks like leak tests, dimension verifications and weight variations occur at multiple junctures. Any irregularities are flagged automatically in real-time for corrective action. Overall qualified rates consistently exceed 97%.

Hygienic Manufacturing

Closed water-cooled forming systems and steam sterilization cycles ensure sanitized napkin surfaces. Critical parts utilize food-grade materials like stainless steel. Clean-in-place systems simplify maintenance. Air consumption of 1800-4800L/min maintains positive pressures.

Customizable Attributes

Manufacturers can customize absorption panels, top sheet features, wing shapes and activation methods per target markets. Rapid changeovers between product lines occur within 15 minutes.

Efficient Packaging

Integrated auto weighing, counting and wrapping systems pack finished napkins precisely according to customer specifications. Multiple formats accommodate various box and pallet sizes for streamlined warehousing and logistics. Packaging productivity achieves over 80%.

Robust and Reliable

Constructed from high-quality components, WOMENG machines operate continuously for over 8 hours daily with minimal maintenance required. Their sturdy frames support cleanroom-grade environments. Dust proof protection safeguards materials.

Energy Efficient

Energy consumption per napkin is minimized through PLC controlled technologies that maximize yields from every material input. Total connected load of individual machines falls within 185-220kW.

With industrial grade productivity of 600-800 napkins per minute, hygienic design practices and flexibility to adapt production, WOMENG machinery is trusted by leading global manufacturers seeking maximized output efficiencies and minimized per unit costs sustainably. Stringent in-house testing ensures consistent performance 24/7/365.

Customizable financing options also make the machines highly accessible to businesses of all scales. Technician and operator training help new clients seamlessly integrate systems. Overall, WOMENG equipment presents a smart investment for any business elevating sanitary product volumes profitably on a global scale.

Quality And Reliability: The Hallmarks Of WOMENG

As a top sanitary napkin packing machine manufacturer and supplier, WOMENG is committed to delivering quality and reliability. Each machine is meticulously tested to ensure it meets the high standards expected by the industry. With WOMENG, manufacturers can rest assured that they are investing in machinery that will deliver outstanding performance and longevity.

Because WOMENG uses branded components to improve production efficiency and machine service life. So our machines have been recognized by customers at home and abroad. At the same time, we also provide OEM and ODM services to build customers machines suitable for their local use. Not only is production efficiency guaranteed, the key is that using our machines allows customers to save more on raw material costs. Why the most of customers from WOMENG call the makers as low cost sanitary napkin making machines.

Join The Revolution: Choose WOMENG

In the fast-paced world of sanitary napkin production, efficiency and quality are key. WOMENG’s sanitary napkin packing machines and fully automatic sanitary napkin making machines offer just that. By choosing WOMENG, manufacturers are investing in a future of streamlined production, quality assurance, and ultimate efficiency. Meanwhile, we not only provide machines for sanitary napkins, but we also manufacture diaper machines for oversea customers. Please contact us for comprehending our machines and negotiation for the cooperation.