Welcome to the world of advanced technology and innovation in the realm of sanitary napkin packaging. In this article, we delve into the game-changing Full Servo technology, designed to revolutionize the process of packaging sanitary napkins. Join us as we explore the capabilities of a state-of-the-art sanitary napkin packing machine equipped with Full Servo technology and uncover how it can enhance efficiency, precision, and productivity in the manufacturing process.

What Is Sanitary Napkin Vending Machine?

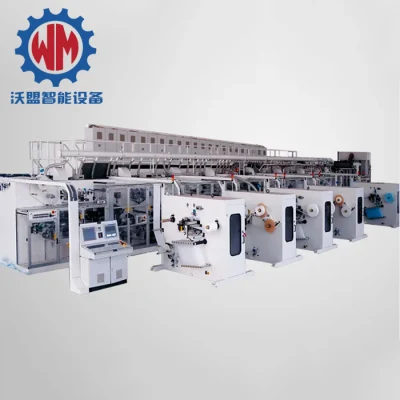

A sanitary napkin vending machine is a specialized vending machine that dispenses sanitary napkins or pads to individuals in need. These machines are typically found in public restrooms, schools, universities, offices, and other public spaces. If consider to buy low-cost sanitary napkin machines, WOMENG may provides quality sanitary napkin machines with competitive price. Besides, we also supply diaper machine in bulk.

Unveiling Full Servo Technology: Redefining Sanitary Napkin Packaging:

Full Servo technology represents a significant leap forward in the field of sanitary napkin packaging. It refers to the utilization of advanced servo motors to control and automate various aspects of the packaging process. With Full Servo technology, each motion and component can be precisely controlled, resulting in improved efficiency, accuracy, and reliability.

Enhanced Efficiency: Streamlining The Packaging Process:

The application of Full Servo technology in a sanitary napkin packing machine brings unparalleled efficiency to the packaging process. By automating tasks such as film feeding, sealing, cutting, and stacking, Full Servo technology minimizes human error, reduces downtime, and optimizes production speed. This allows manufacturers to achieve higher output rates while maintaining consistent quality.

Precision And Flexibility: Customized Packaging Solutions:

Full Servo technology empowers manufacturers to achieve precise and customized packaging solutions for different types and sizes of sanitary napkins. The advanced servo motors enable precise control of the sealing pressure, film tension, and cutting length, ensuring a snug and secure package for each individual napkin. This level of precision allows manufacturers to cater to diverse market demands and meet the unique packaging requirements of their customers.

Improved Product Quality: Eliminating Defects And Waste:

With Full Servo technology, manufacturers can significantly reduce product defects and waste during the packaging process. The precise control over the sealing pressure and cutting length minimizes the risk of improper sealing or inaccurate cutting, ensuring that each package meets the highest quality standards. This not only enhances customer satisfaction but also reduces material waste and increases overall production efficiency.

Seamless Integration: Full Servo Technology And Industry 4.0:

Full Servo technology seamlessly integrates with the principles of Industry 4.0, enabling real-time monitoring, data collection, and analysis. Manufacturers can access valuable insights regarding production performance, machine maintenance, and quality control. This data-driven approach allows for proactive decision-making, predictive maintenance, and continuous improvement in the packaging process.