Investing in a good quality underpad production line or sanitary napkin production line, such as a full servo underpad-making machine, is essential for manufacturers seeking to meet the growing demand for high-quality underpads. The advanced features and benefits of these machines, including high production efficiency, precision, and flexibility, contribute to increased productivity and profitability.

Understanding Full Servo Underpad Making Machine:

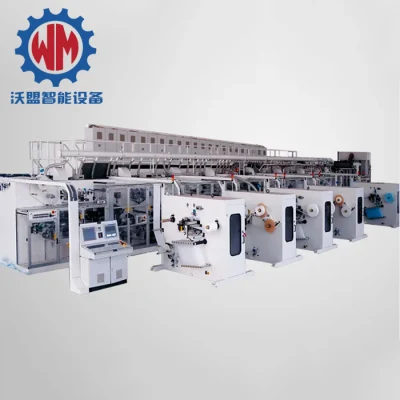

A full servo underpad-making machine is an automated production line specifically designed for the manufacturing of underpads. It incorporates advanced servo technology, which provides precise control over the entire production process, ensuring consistent product quality and efficiency.

Benefits of Full Servo Underpad Making Machine:

- High Production Efficiency: Full servo underpad-making machines operate at high speeds, producing a large volume of underpads in a shorter time frame. This increased efficiency helps manufacturers meet market demands and optimize production costs.

- Precision and Accuracy: Servo technology enables precise control over the movement of the machine’s components, resulting in accurate cutting, folding, and sealing of the underpads. This precision ensures consistent product quality and minimizes defects.

- Reduced Labor Costs: The automation provided by a full servo underpad-making machine reduces the need for manual labor, resulting in lower production costs. Manufacturers can allocate resources to other critical areas of their operations.

- Flexibility and Versatility: These machines offer flexibility in terms of the types and sizes of underpads that can be produced. By simply adjusting the machine’s settings, manufacturers can produce different products to meet diverse market needs.

Key Features of Full Servo Underpad Making Machine:

- Precise Cutting and Folding: Servo-driven cutting and folding mechanisms ensure accurate dimensions and consistent folding patterns, resulting in high-quality underpads.

- Ultrasonic Sealing: Ultrasonic sealing technology is employed to create strong and leak-proof seals, enhancing the overall quality and durability of the underpads.

- Stacking and Packaging: The machine can be integrated with an automatic stacking and packaging system, streamlining the production process and reducing manual handling.

- Automatic Raw Material Feeding: The machine can be equipped with an automatic raw material feeding system, ensuring a continuous supply of materials for uninterrupted production.